A Source Factory Built for Long-Term Supply

CHEUNGG STEEL operates as a direct manufacturing factory, not a trading intermediary. All core fencing and mesh products are produced under controlled factory processes, enabling:

-

Consistent specifications across repeated orders

-

Stable raw material sourcing

-

Direct control of welding, galvanizing, and coating processes

-

Predictable lead times for project and stocking orders

This factory-based model is particularly important for distributors and contractors who require repeatability, not one-off samples that cannot be replicated at scale.

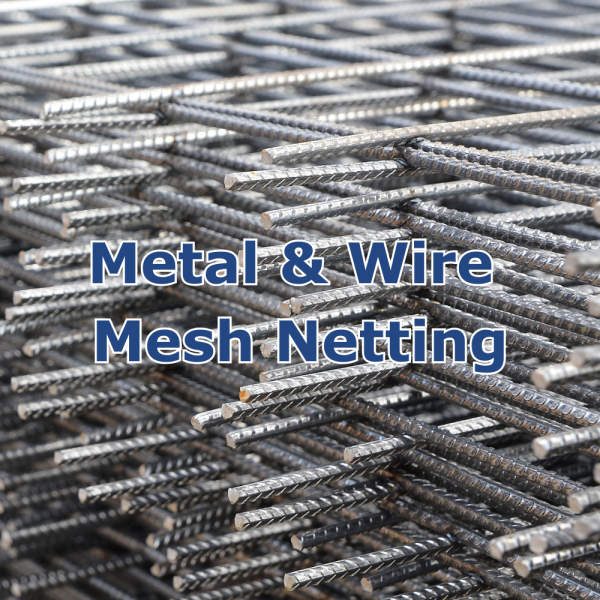

Product Systems Designed for Security Projects

CHEUNGG STEEL supplies a full range of security and perimeter systems, commonly used in commercial, industrial, and infrastructure projects:

-

358 Anti-Climb Fence Systems (airport, utilities, high-security zones)

-

3D / 2D Welded Mesh Fencing

-

Temporary Fencing Systems (construction and event security)

-

Chain Link Fence Systems with razor wire or barbed wire

-

Reinforcing Mesh & Trench Mesh for civil works

-

Custom steel mesh solutions for project-specific requirements

Each product category is supplied as a system, including panels, posts, clamps, fixings, and accessories, ensuring compatibility and ease of installation on-site.

Quality Consistency for Large-Volume Buyers

For large distributors and engineering contractors, the biggest risk is not price—it is inconsistent quality across shipments. CHEUNGG STEEL focuses on process control rather than visual marketing.

Key quality practices include:

-

Controlled wire diameter and mesh aperture tolerances

-

Stable welding parameters to ensure uniform weld strength

-

Hot-dip galvanizing or galvanizing + powder coating systems suitable for long-term outdoor use

-

Batch-based production records for repeat orders

This approach supports long-term supply programs, framework agreements, and multi-site projects where consistency matters more than short-term cost savings.

Engineered for Contractors, Not Just Traders

CHEUNGG STEEL works closely with engineering and construction partners to support:

-

Drawing-based production

-

Custom heights, apertures, post sections, and fixing methods

-

Packaging adapted for container efficiency and site handling

-

Documentation support for inspections and approvals

The factory is accustomed to working under project timelines, including phased deliveries and container optimization for overseas sites.

Stable Delivery for International Markets

With extensive experience in exporting fencing and mesh products, CHEUNGG STEEL understands the logistical expectations of international buyers:

-

Containerized shipping (20GP / 40GP / 40HQ)

-

Clear packing lists and loading plans

-

Flexible Incoterms: EXW, FOB, CFR, CIF

-

Production schedules aligned with project milestones

For distributors, this means predictable restocking.

For contractors, it means reduced risk of site delays.

A Manufacturing Partner, Not a Short-Term Supplier

CHEUNGG STEEL positions itself as a long-term manufacturing partner for:

-

National and regional fence distributors

-

Security system integrators

-

Infrastructure and civil engineering contractors

-

Government and utility project suppliers

The focus is not on single transactions, but on repeatable supply, technical alignment, and operational reliability.

Conclusion: Security Starts at the Factory Level

In global security projects, performance on site begins with discipline in manufacturing.

By combining direct factory control, engineering-oriented production, and export-focused logistics, CHEUNGG STEEL delivers fencing and mesh systems that international buyers can rely on—project after project, shipment after shipment.

We do not simply sell fences.

We produce security for your business.

Reviews

There are no reviews yet.